This was important to share. I did not write it, but it is about things relevant to my family.

- July 15, 2021

By: Kenneth Rosa

The USA is a constitutional republic and the rule of the majority never exceed the importance of the individual’s rights. The executive, legislative, and judicial branch are to ensure that individual’s rights are protected by each. The American people let the three collaborate to ignore the responsibilities each are supposed to provide. Each branch working to protect us from the next.

Let’s stay out of the weeds on the ridiculousness to have a license from the state to marry anyone of our choice. This allows jurisdiction of the state to infringe upon our divorces and custody agreements. Consider this: 1 one out of every 2 two marriages will end in divorce. 4000 four thousand people a day will enter into a divorce nationwide. Legislatures are responsible for laws to protect parents and the rights of the child to both parents equally in marriage and divorce.

Yet we only have 2 two states required by law to protect the rights of each parent and the child. Kentucky was first and Arkansas followed in 2021 with an equal shared parenting rebuttable presumption law. Many states have “presumption of equal shared parenting” in the language of the state laws. The family courts aren’t following the laws or recommendations to have equal rights to the child with any clear codification in any other states despite the recommendation.

In the 2010 US Census mothers received custody 83 eighty three percent of the time. In the 2020 US Census mothers still received custody seventy-nine plus percent of the time. That’s not even close. There is no debate that there isn’t clear judicial bias, discrimination, and deprivation of human rights happening. Studies suggest when a father is removed forcibly by a court order that bad things happen to society. The child is 70 plus percent more likely to fail in life but the trend continues. I thought it was about the “best interest of the child”? The custodial mother has stayed in the 80th eighty percentile since the 1990’s. This isn’t an article about fathers against mothers or vice versa though.

The Color of Law

Let’s focus on the color of law being erased in the family court. Established laws and court orders are being circumvented by the judiciary. They have become above the law and a lawless society of elites. These elites hide behind their BAR membership as attorneys. The state BARS collect millions in yearly dues. The dues ensure your BAR license will be protected at all costs unless you become a whistleblower. If an investigation occurs a committee will investigate its own members. Investigations are hushed unless you messed up enough to be on the news. They’re not punishing you because you did something unethical. They’re punishing you because they can’t hide it.

These elites hide behind quasi-judicial immunity as a GAL (guardian ad litems). They can routinely violate your rights to your own children in their recommendations that judges always accept. These elites hide behind this immunity as therapists and can routinely violate your rights to your children. An example of a HIPPA violation would be doxing a parents medical records to their minor children or other members of the public. Similar actions outside a family court room would cause legal and professional ramifications. No actions will be taken against you if your capacity was performed for the family courts.

The last elites hiding behind absolute judicial immunity are supposed to be the most trained. The guardians of the color of law. They are our family court judges. Elected judges give us a way to hold them semi accountable. What about ones that are appointed? You can submit a judicial complaint. You probably have better odds of winning the lottery than having a judge held accountable for their actions against you. After all its only your constitutional rights that are being violated. How do members of the family court get away with violations of due process, bias, discrimination, and the deprivation of human rights? With simple sentences: “To err on the side of caution”, “in the best interest of the child”, “preponderance of evidence”. There goes your due process and there is no way to hold them accountable.

The Missouri Family courts in ST. Louis County have been in the national news for most of 2020 and 2021. A video of the county GALS was leaked. Sarah Pleban and Elaine Pudlowski are bragging they won’t be held accountable and that the “judges are in on it”. They like to call their deprivation of human rights “Cash For Kids LLC”. Shavon Harris is on the state judicial oversight committee. She is also present on the video coaching and observing this unethical behavior. No one has been disciplined, arrested, disbarred, or held accountable to date that I am aware of. They are back to doing business as usual. https://youtu.be/z_Re_bX118k I have requested a meeting with the Missouri Governor and to date the request has been ignored.

Collin County Texas

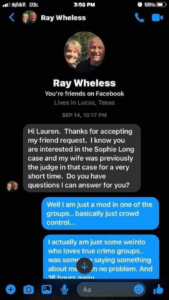

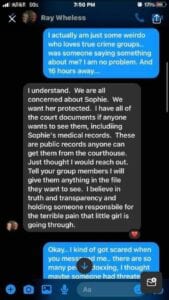

Meanwhile in Collin County, Texas we have a case under Judge Ray Wheless. Does anyone think this judge is following ethical conduct by doxing a 10-year-old child’s medical records? This is the presiding judge of Collin County Texas? If he is having these type of communications with members of the public what type of ex-parte communications were going on behind the scenes with the GAL and Amicus?

Some will remember the Michael Long case. His daughter who is under 10 years old S* made a spontaneous utterance on video that mom’s boyfriend was sexually abusing her. I have chosen to not print the child’s name due to her age. Perhaps Judge Wheless should have shown her the same courteous behavior when discussing the case with a random person. Millions have viewed the video since August 2020. There was a viral hashtag #SaveS@!#$% with 23 plus million views on Tik Tok alone. Once again, I have chosen to leave the child’s name out due to her age.

A temporary order in September 2020 gave Michael custody of all three children. A visitation order for the minor boys to go around their mother followed soon after. Strict conditions forbid the boyfriend from the children after allegedly committing a sex crime and an ongoing criminal investigation was taking place. In February 2021 on mom’s parental time the boys were around the boyfriend. This is a direct violation of the court order. He flipped a recreational vehicle resulting in one of the minor boys breaking an arm. The break required surgery to repair it.

The attorneys representing Long began to feel their BAR licenses were being threatened in this case. All legal counsel has stepped down leaving Long to go pro-se while he feels the court actors are biased against him. Attempts to place the daughter back with a mother who refuses to abide by a court restraining order tend to lend credibility to his claims. Breaking that order resulted in serious bodily injury to another Long child.

Recusals submitted in May 2021, lead to Regional Judge Wheless voluntarily recusing. The Texas Supreme Court ordered Judge Stubblefield to preside over the matters. Insert Judge Michael Snipes. He has refused to recuse himself from the case after the higher courts order. He doesn’t believe the laws apply to him.

I sent Judge Snipes a FOIA request inquiring why he is using a personal email account for state business instead of a government account. I also inquired about ex-parte communications with his newly appointed GAL Stephanie Martin or newly appointed Amicus John Helms. It’s no surprise Snipes appointed Martin. She used to work with him at the district attorney’s office. It’s also no surprise that Helms is his old business partner. Nothing to worry about now that the old gang is back together again. Judge Snipes has not responded. The Texas Executive Director of “State Commission on Judicial Conduct” did inform me she had no records available to provide.

Michael Long filed a federal lawsuit because of numerous filings at the state level being ignored by Judge Snipes. Snipes heard the motions himself on July 7th, 2021. He ordered the minor child turned over to Grandma. She was violently attempting to remove S* from the father in the viral video. Grandma is to give S* to moms sister residing in North Carolina. I assume Judge Snipes missed cases that a child may not be removed from a parent and given to a third-party conservator without a clear and convincing finding of abuse in the state of Texas.

There is a gag order against Michael Long leaving no choices to protect his children. Unethical and unconstitutional orders must be ignored. How do you protect yourself from the law when the law is what is harming you? Judge Snipes continues these egregious actions to place the child back in the circle of people alleged of abusing her. This is the type of injustice the fathers and non-custodial moms of America have to endure. Judge Snipes has turned up his nose to the Texas Supreme Court. The fifth court of appeals has received a 445-page mandamus filed on Long’s behalf. Texas Case #05-21-00574-CV. Will they get it correct? Is this really what it looks like to be a father or a non-custodial mother if you’re the targeted parent by the family court in the USA?

Judicial Immunity

We have a lawless elite group covered in absolute or quasi-judicial immunity. This is the American family courts? Most people don’t know the immunity legal theory hasn’t been around forever. The theory was put in place in the 1960’s. The legislatures must strip this bogus scheme from the family courts to operate with no accountability and under the color of the law. We must reclaim our society, our families, and our courts. Stop depriving parent’s equal human rights and hold the lawless family courts accountable!

The world is watching the revolt in Cuba. The Cuban people want freedom from their oppressive government. They want basic human rights for all, not just the government. The Cuban people are waving American flags to symbolize the freedom and model they want to achieve. If the USA is going to be the beacon model for all countries to follow, we must fix our own broken government. Start with our children’s rights to both parents. We must restore the color of law that’s been erased. This isn’t how it was intended to be.

Kenneth Rosa

Media Manager, TFRM

#TFRM #MichaelLong #fathersmattertoo #Rosa