Many years ago (1970s) when I was in living in Miamisburg, Ohio just outside of Dayton and attending the technical training center for NCR, I would go into Dayton and peruse the huge surplus store of Mendelsen’s. Multi floors of all kinds of wonderful things. More industrial than today when industry in the area was booming and the NCR factory still stood as a monument to times past. When companies were careers, employees were family and the mechanical cash register reigned the retail marketplace. I could spend hours imagining uses for the discards of industry.

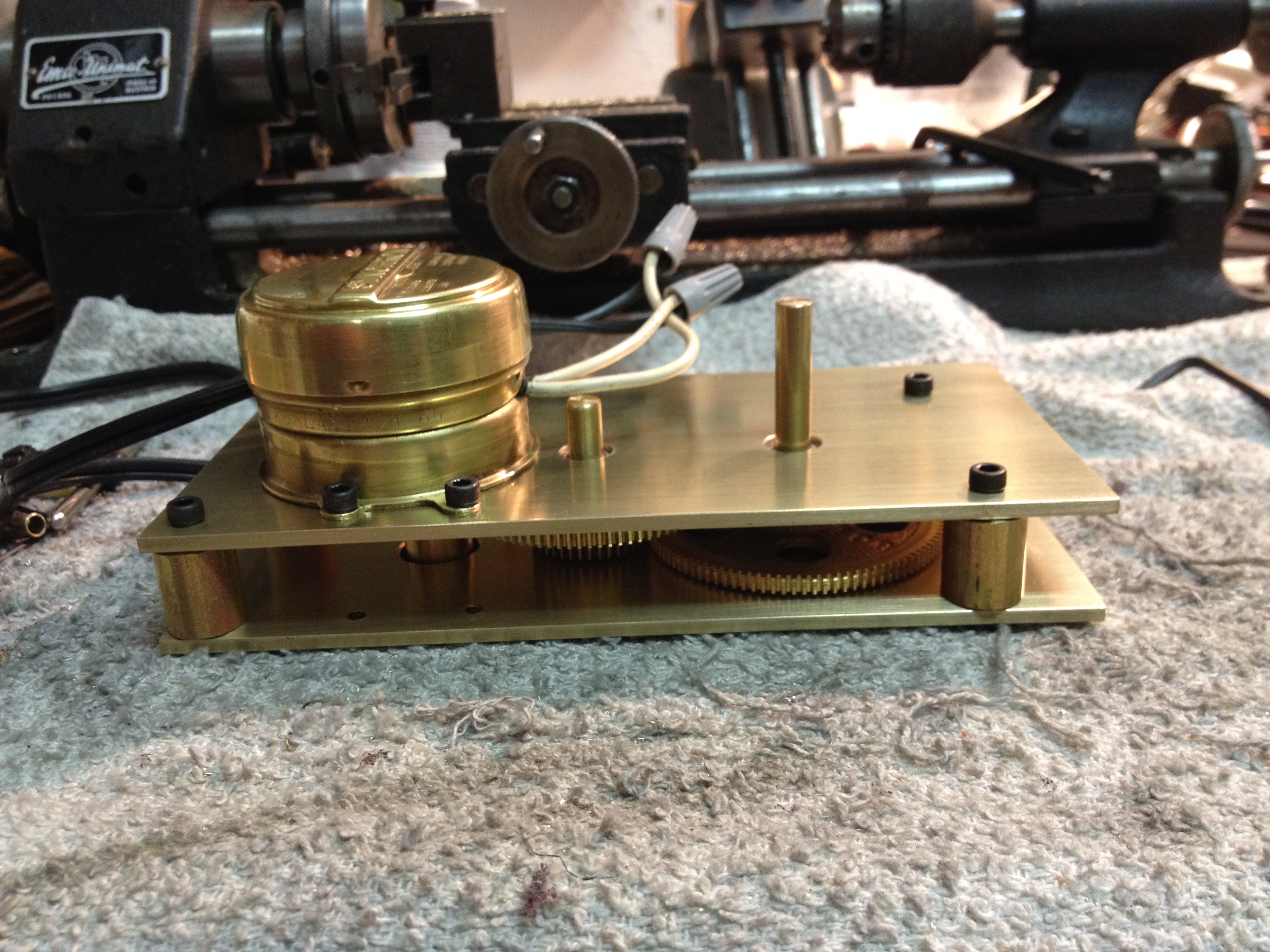

While there I picked up a Synchron Timing Motor (110 volt, 20 rpm) that had a brass case. I liked it, but had no real use for it at the time.

When looking for a timing motor for the clock, I came across this one that had been packed away since 1972 (43 years). I don’t throw away much. Anyway I felt that this was a good place to start and the price was right.

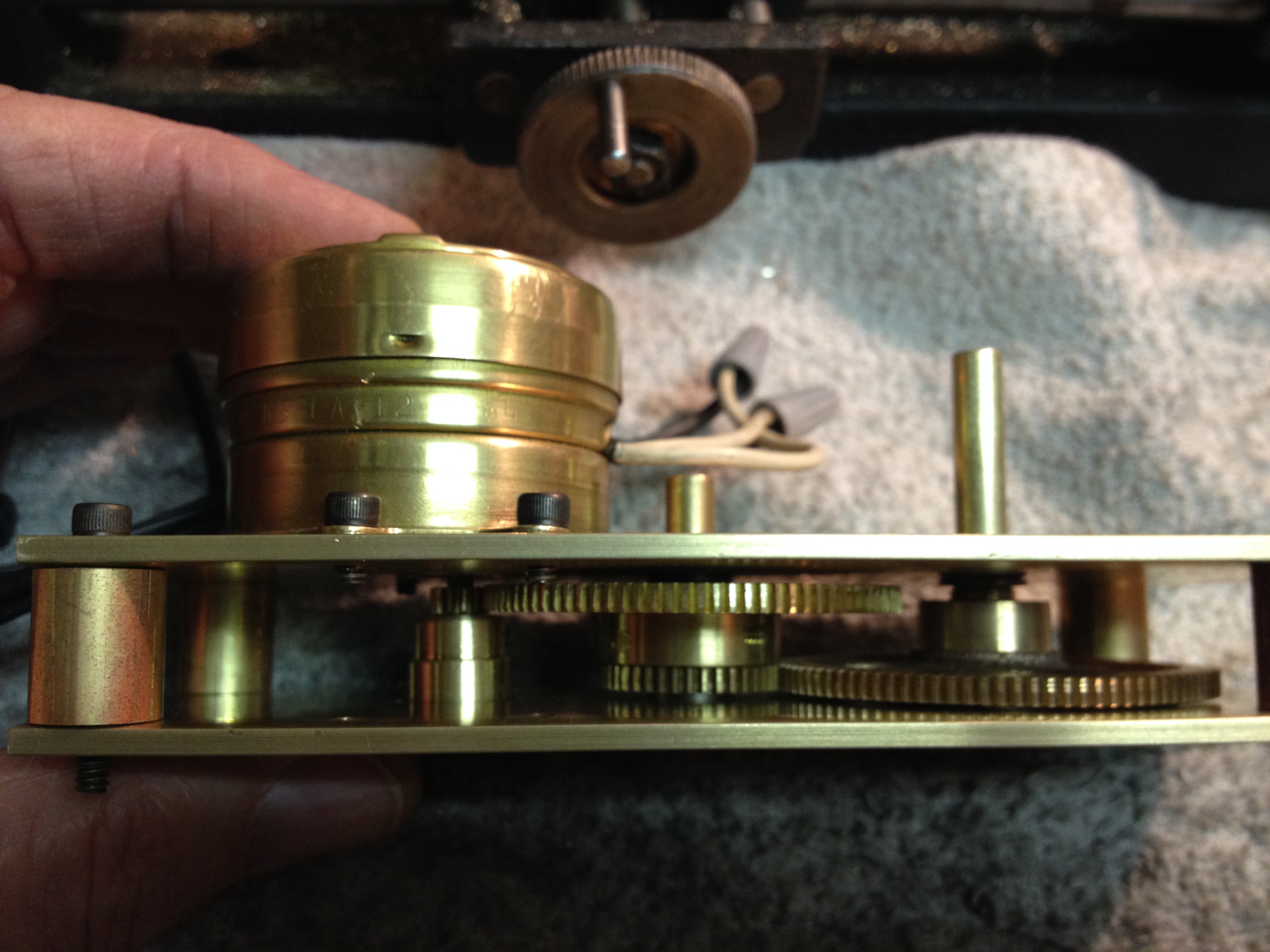

I knew I wanted the clock to be around after I had sought other adventures in the afterlife, so a solid drive was important. It would have to be brass, well geared and have bearings for the shafts.

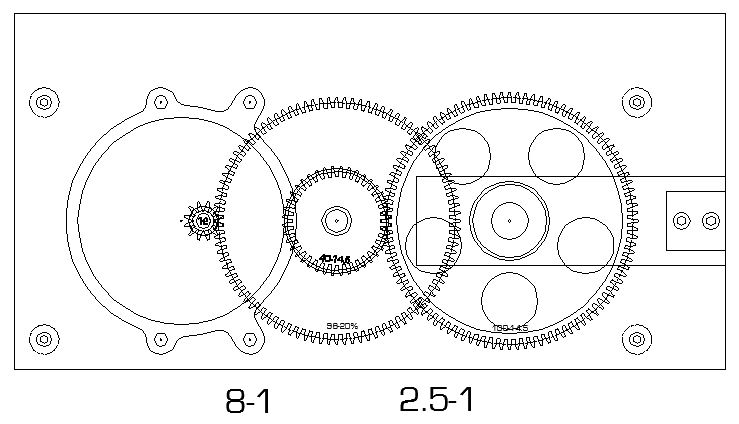

Figuring out the ratios for the gears was the next thing. I had to take 20 rpm down to 1 rpm if I was going to use a screw type lift for the balls. As there may be a need for extra power before the project is completed. Searching for gears was something new and learning about “Pitch”, Pitch Diameter”, “Bore”, “Spur”, “Bevel” and the like was new to me. Plenty of companies would make custom gears for a price. I needed something that was available off the shelf and not requiring I mortgage the house. Boston Gear has the right products and selection. I could find cheaper, but not made in America and not brass.

I put pen to paper so to speak, actually a little AutoCAD and came up with a layout that would work. Finding the right size spur gears in stock to do the job from MSC Supply worked well and with good service.

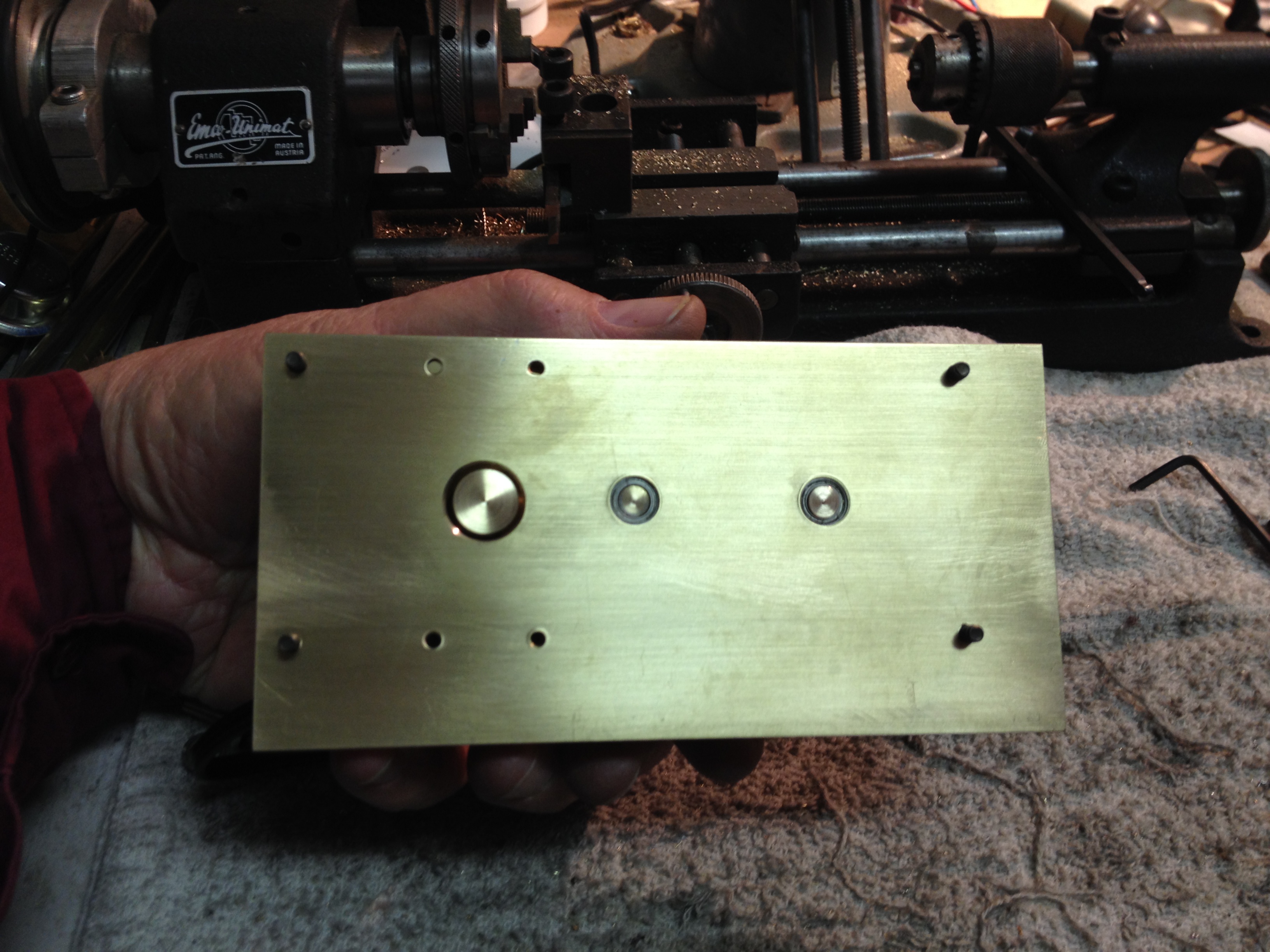

It took some searching before I found bearings that would work for the .25in shafts, but VBX Bearings had a great selection.

Brass plate .125 was used for the frame sides with spacers turned out of 1/2″ brass stock.

So it has taken a month since I started with design, ordering gears & bearings to put this together, but I am pleased with the outcome. It runs smooth and with the ball bearings, should last a good while.

The extra shaft that turns at 2.5 rpm will find a use. If not, it was needed anyway.

Now to start on lifting the balls.